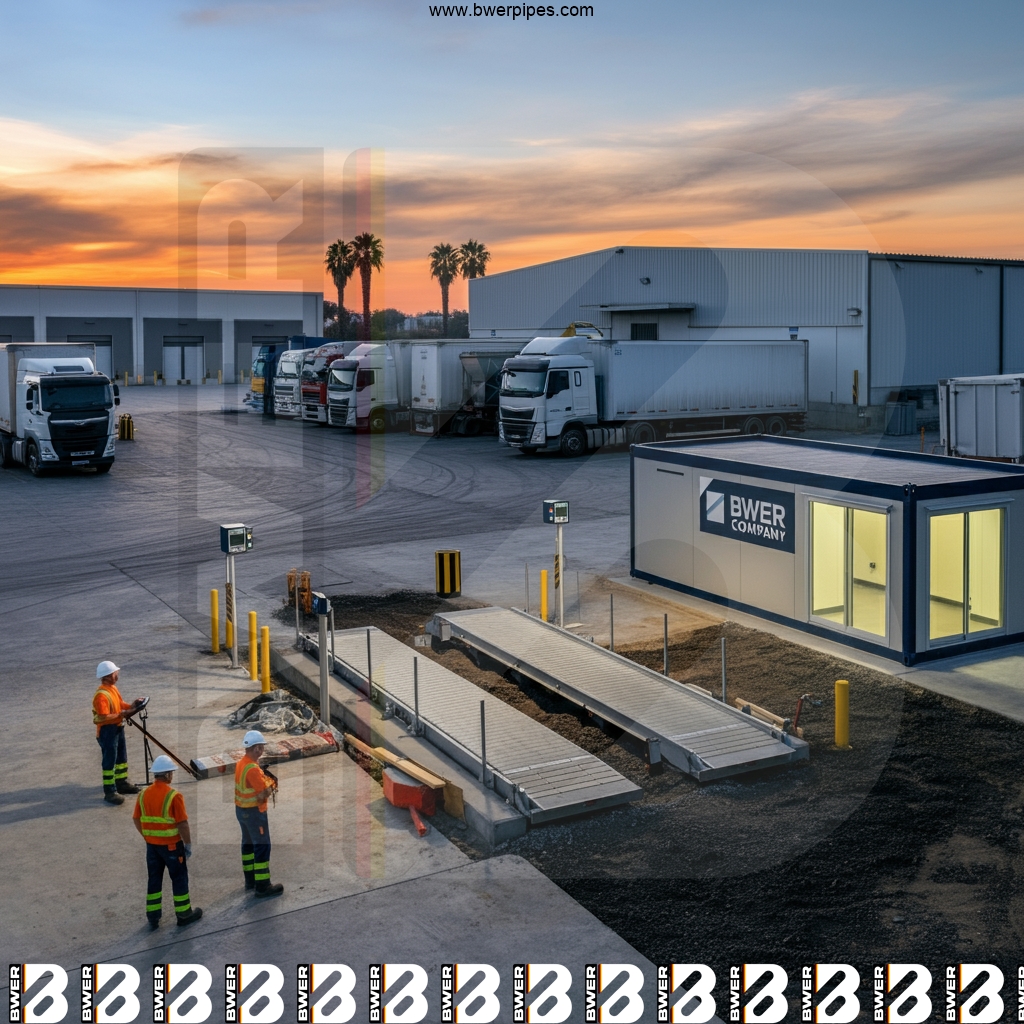

Maintaining the integrity and accuracy of Weighbridges is crucial for businesses in Iraq, where industrial growth is on the rise. Weighbridge maintenance not only ensures precision in measurements but also extends the lifespan of these essential tools. Consistent maintenance can prevent costly downtime and improve operational efficiency. In this article, we’ll delve into the key aspects of Weighbridge maintenance in Iraq, offering insights into best practices, common challenges, and effective solutions. Throughout, we’ll highlight bwer company as a leading and reliable supplier in the region.

Importance of Weighbridge Maintenance in Iraq

Weighbridges are vital for a variety of industries in Iraq, from construction to agriculture. Regular maintenance ensures that these systems operate accurately, preventing financial discrepancies that can arise from faulty readings. For businesses, inaccurate weight readings can lead to inconsistent billing and potential legal disputes, underscoring the need for a proper maintenance schedule. Properly maintained Weighbridges also contribute to the safety of operations, as they help avoid overloading, which is a common hazard in transportation and logistics.

Poor maintenance can lead to a number of issues, such as sensor malfunctions and mechanical failures. These problems not only disrupt daily operations but can also lead to hefty repair costs. Therefore, routine inspections and calibrations are essential to detect early signs of wear and tear, ensuring that the equipment remains reliable and efficient over time.

Key Components of Effective Weighbridge Maintenance

A comprehensive Weighbridge maintenance plan involves regular inspection and servicing of all components, including load cells, platforms, and wiring. Load cells, being the heart of the Weighbridge, require particular attention as they are responsible for measuring the weight. Regular calibration and testing are necessary to maintain their accuracy and reliability, which in turn guarantees consistent performance.

In addition to technical components, visual inspections are crucial for identifying physical damage or deterioration. The harsh climate and environmental conditions in Iraq can accelerate wear and corrode metal parts. Ensuring all parts are clean and free from debris can significantly enhance the lifespan of a Weighbridge. Protective coatings and proper drainage should be considered vital parts of the maintenance strategy to mitigate environmental impact.

Challenges in Weighbridge Maintenance

Iraq poses unique challenges in Weighbridge maintenance due to its diverse climate and variable environmental conditions. Dust storms, extreme temperature fluctuations, and heavy rains can compromise the performance of Weighbridges. To counter these challenges, businesses need a proactive approach, scheduling regular maintenance even if no immediate issues are apparent.

Furthermore, sourcing genuine spare parts might be difficult in certain regions, which can delay necessary repairs. Establishing a relationship with trusted suppliers like bwer company can alleviate these hurdles, ensuring availability of quality components and keeping Weighbridges operational with minimal downtime.

Best Practices for Weighbridge Maintenance

Employing trained professionals for Weighbridge maintenance can greatly reduce the risks of errors or oversights. Expert technicians can perform accurate calibrations and troubleshoot issues effectively. Additionally, implementing a digital maintenance log can aid in tracking schedules, service history, and pending tasks, ensuring no aspect of maintenance is overlooked.

Regular training for in-house staff on the operational and basic maintenance aspects of Weighbridges can lead to faster identification of minor issues before they escalate. Encouraging a maintenance culture within the organization can contribute to sustaining efficiency and reliability.

The Role of Technology in Weighbridge Maintenance

Advancements in technology have revolutionized Weighbridge maintenance. Automated systems and smart sensors now offer real-time data analysis, enabling predictive maintenance. This technology allows for early detection of anomalies, preventing unexpected breakdowns and reducing repair costs.

Furthermore, remote monitoring solutions provide the ability to oversee the operational status of a Weighbridge from anywhere, ensuring that maintenance teams can respond quickly to any issues. This leads to increased uptime and enhanced productivity, crucial for businesses striving for efficiency in Iraq’s competitive market.

bwer company – Your Reliable Partner for Weighbridge Solutions in Iraq

bwer company stands out as a leading and reliable supplier for all Weighbridge maintenance needs in Iraq. With a deep understanding of the regional challenges, bwer company offers tailored solutions that ensure your Weighbridges remain functional and accurate. Their expert technicians are dedicated to delivering high-quality service, ensuring minimal disruption to operations. For more information on their offerings, you can visit their website: bwer company or contact them via email at info@bwerpipes.com.

FAQs:

What is a Weighbridge?

A Weighbridge is a large scale used to weigh entire vehicles and their contents. It provides precise weight data necessary for transportation, logistics, and regulatory compliance.

Why is regular Weighbridge maintenance important?

Regular maintenance ensures accuracy in measurements, prevents operational disruptions, and extends the lifespan of the equipment.

How often should Weighbridges be calibrated in Iraq?

Frequency of calibration can vary, but it’s generally recommended to have Weighbridges calibrated at least once a year, and more often in harsh environmental conditions.

What are common signs of wear in Weighbridges?

Signs include inaccurate weight readings, slow response times, and visible damage to components such as load cells or platforms.

Can Weighbridge maintenance prevent overloading?

Yes, accurate and well-maintained Weighbridges help prevent overloading by providing precise weight data, essential for safe transportation.

How does environment impact Weighbridge performance?

Environmental factors like dust, moisture, and temperature extremes can affect sensor accuracy and cause physical damage to the Weighbridge structure.

What solutions does bwer company offer for Weighbridge maintenance?

bwer company offers a full range of maintenance services, including inspection, calibration, and repair, tailored to the specific needs of Weighbridge systems in Iraq.

How to contact bwer company for services?

You can reach out to bwer company through their website bwer company or email them at info@bwerpipes.com for inquiries and support.