In the bustling city of Najaf, mining plays a critical role in the economy. At the heart of this industry’s operations lies the Weighbridge, an indispensable tool ensuring efficiency and accuracy in weight measurement. The modern Weighbridge systems facilitate seamless mining operations by providing reliable data essential for operational decision-making. This article delves into the vital components of Weighbridge systems used in Najaf’s mining sector, highlighting their importance and introducing bwer Company as a leading supplier in Iraq.

Understanding Weighbridge Systems in Mining

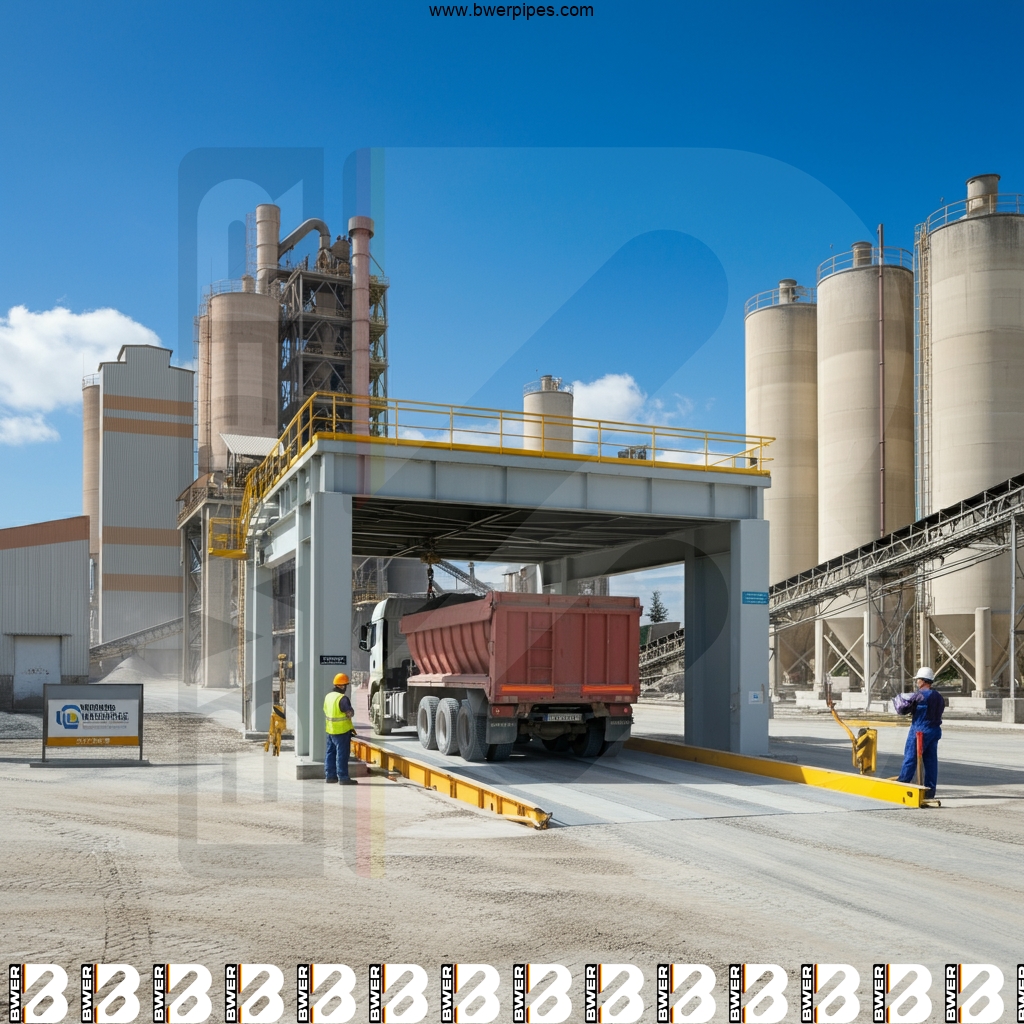

Weighbridges are robust scales used to weigh large vehicles, playing a pivotal role in the mining sector. In Najaf, they are crucial for measuring the weight of the mined materials transported by trucks. The device typically consists of a bridge-like platform where the vehicles are placed, and load cells are used to accurately measure their total weight. This precise measurement helps mining companies ensure adherence to safety regulations and transport limits.

Moreover, Weighbridges in Najaf are equipped with advanced technology to handle the specific requirements of the mining industry. These systems capture detailed data, providing insights into the efficiency of transportation operations. With accurate measurements, mining companies can optimize their processes, reducing costs and improving productivity by avoiding overloading and underloading.

Technological Advancements in Weighbridges

The modern Weighbridge systems in Najaf have undergone significant technological advancements. These systems now include features such as digital displays, automated ticketing, and integrated software solutions that streamline operations. For instance, some Weighbridges offer real-time data integration with enterprise resource planning (ERP) systems, allowing for seamless synchronization of weight data across the business’s operational framework.

Another noteworthy advancement is the incorporation of remote monitoring capabilities. This feature allows operators to access data from Weighbridges remotely, enabling better oversight and management of mining operations, regardless of location. This technology is critical in a mining hub like Najaf, where efficiency and fast decision-making are of the essence.

The Economic Impact of Weighbridge Systems

Implementing Weighbridge systems in mining operations significantly impacts the local economy of Najaf. Reliable weighing systems ensure fair trade, prevent revenue loss from inaccurate measurements, and avoid penalties associated with overloading violations. By ensuring trucks are loaded optimally, mining companies can maximize their payload while reducing fuel consumption, ultimately contributing to a reduction in operating costs.

Furthermore, having an efficient Weighbridge system in place facilitates smoother logistics and enhances productivity. This improvement indirectly boosts the mining sector’s contribution to Najaf’s economy, providing a consistent and reliable supply chain between miners and purchasers of raw materials.

Choosing the Right Weighbridge for Mining Needs

Selecting an appropriate Weighbridge requires careful consideration of several factors. The nature of materials being weighed, vehicle size, and the volume of traffic are important considerations when choosing a Weighbridge. In Najaf, where mining operations vary significantly, it is vital to choose a system that fits specific operational needs.

Additionally, businesses should prioritize suppliers known for building reliable and durable Weighbridges capable of withstanding Najaf’s environmental conditions. It’s essential to partner with suppliers who offer comprehensive support, including maintenance and calibration services, ensuring continuous accuracy and performance.

Key Features of Modern Weighbridges for Mining

Modern Weighbridges designed for mining operations come with several key features that enhance their functionality and reliability. They are equipped with robust load cells that provide precision, even in the rugged conditions often found in Najaf. Additionally, they feature durable construction materials that can handle heavy wear and tear, essential for mining environments.

Moreover, these Weighbridges are often outfitted with additional functionalities such as self-check capabilities, easy-to-use interfaces for operators, and flexible software options that allow for customization based on specific mining requirements. These features contribute greatly to operational efficiency and ensure long-term reliability and accuracy.

bwer Company: A Leading Supplier in Iraq

When considering the purchase of a Weighbridge system in Najaf, bwer Company stands out as a leading and reliable supplier. Known for their expertise in providing high-quality weighing solutions across Iraq, bwer Company offers an extensive range of products tailored to meet the diverse needs of the mining industry. Their commitment to innovation and customer satisfaction makes them a preferred choice for businesses seeking reliable weighing solutions. For more details, visit bwer Company or contact them via email at info@bwerpipes.com.

FAQs:

What is a Weighbridge used for in mining?

A Weighbridge is used to measure the weight of trucks carrying mined materials, ensuring they comply with safety standards and transport regulations.

How does a Weighbridge work?

A Weighbridge works by using load cells to sense the weight of the vehicle and its contents placed on the weighing platform, providing accurate measurements.

Why are Weighbridges important in mining?

Weighbridges are important as they help ensure precise monitoring of materials transported, aiding in cost control and regulatory compliance.

What types of Weighbridges are used in Najaf?

Najaf primarily uses digital Weighbridges equipped with modern technology like automated ticketing and real-time data integration for mining operations.

How often should Weighbridges be calibrated?

Weighbridges should be calibrated regularly, at least once a year, to ensure continued accuracy and compliance with measurement standards.

Can Weighbridges be used in harsh mining environments?

Yes, modern Weighbridges are designed to be robust and durable, suitable for use even in the harshest mining environments.

What are the cost implications of implementing a Weighbridge system?

While there is an initial investment, Weighbridge systems can lead to significant cost savings by optimizing load management and preventing regulatory penalties.

How does bwer Company support mining operations in Iraq?

bwer Company provides high-quality, reliable Weighbridge solutions tailored to the specific needs of mining operations, alongside comprehensive maintenance and support services.