Mining operations in Maysan have been gaining momentum, and the use of advanced mining platform scales is at the forefront of this growth. These scales, essential for ensuring precision and efficiency in metal extraction, are transforming how businesses operate. This article delves into the intricacies of mining platform scale in Maysan, offering a comprehensive guide on their functionalities and importance. Read on to understand why mining platform scales are vital, and discover how bwer company stands out as a leading supplier of these essential tools in Iraq.

The Importance of Mining Platform Scale in Maysan

In the mining sector, precision is crucial for competitiveness and safety. Mining platform scales play a pivotal role in weighing heavy loads of extracted materials. Accurate weight measurements ensure proper resource management, minimizing errors in inventory and logistics that can lead to financial losses. In Maysan, where mining activities are rapidly expanding, these scales are becoming indispensable.

With the terrain and conditions in the Maysan region often challenging, platforms scales engineered for harsh environments are essential. They must endure robust use while delivering precise measurements. This necessity propels mining companies towards investing in high-quality scales that provide reliability under strenuous circumstances, ensuring that operations maintain their efficiency and safety standards.

Types and Features of Mining Platform Scales

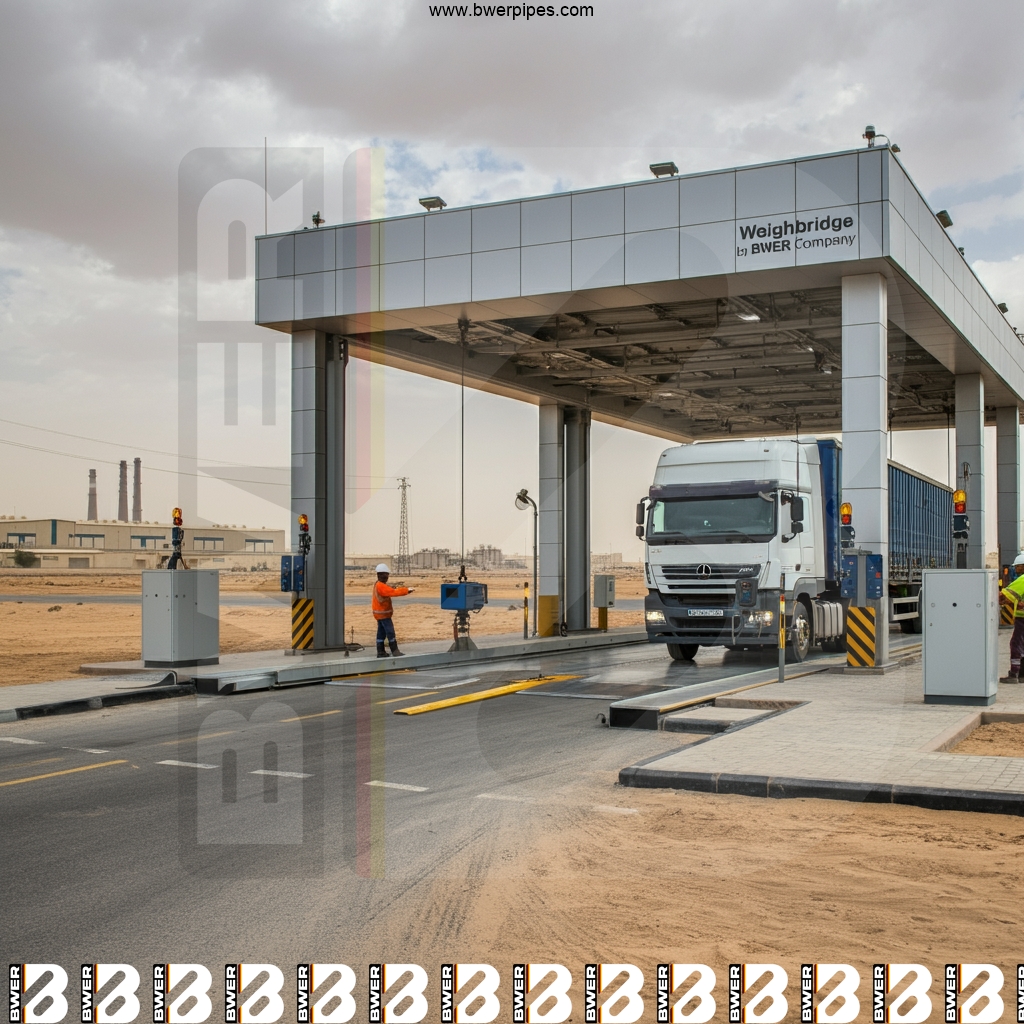

Various types of mining platform scales are employed in Maysan’s mining operations, each tailored to specific needs. From truck scales to conveyor belt scales, the selection depends heavily on the extraction method in use. Truck scales, for example, are invaluable for weighing large logistical loads, while conveyor belt scales integrate seamlessly to offer continuous weight measurement of materials.

Advanced features such as digital readouts, connectivity options, and robust builds enhance the functionality of platform scales. These features allow real-time data analysis, which is pivotal for operational decision-making. Adopting these modern weighing scales is not just an upgrade but a necessity to keep up with the fast-paced advancements in mining technology.

Impact of Mining Platform Scales on Productivity

The productivity boost from using mining platform scales is noteworthy. Accurate weight data minimizes material handling errors, leading to smoother processing workflows. Moreover, it allows mining operations to optimize their resource use, cutting down unnecessary costs due to errors in ore quantification.

In Maysan, where mining is a significant economic driver, the efficiency introduced by platform scales impacts the broader economy positively. By streamlining logistic operations, they enable mining companies to maintain productivity even when demand fluctuations occur. This scalability potential is essential in managing both down periods and times of heightened activity in the mining sector.

Incorporating Technology in Mining Platform Scales

The integration of technology into mining platform scales is transforming their application. Automation and IoT (Internet of Things) capabilities are being embedded into scales to improve accuracy and provide remote monitoring solutions. This technological evolution facilitates data centralization, allowing companies to optimize their operations and reduce manual interventions.

For the Maysan region, these advancements could lead to a breakthrough in how data-driven insights are used to enhance performance. Automated scales reduce the need for on-site personnel, lowering labor costs while increasing safety by minimizing human intervention in potentially hazardous zones.

Challenges and Solutions in Utilizing Mining Platform Scales

Despite the evident benefits, several challenges exist in deploying mining platform scales in Maysan. These include high initial investment costs, the need for regular calibration, and potential difficulties in integrating with existing systems. However, solutions are available. Consideration of lifecycle costs rather than just initial expenses can provide a better ROI perspective.

Additionally, partnering with premier service providers like bwer company, known for their reliability in Iraq, can address integration issues. They offer support in scale deployments and provide ongoing maintenance to ensure that the scales operate at peak efficiency.

Why bwer Company is Your Go-To for Mining Platform Scales in Iraq

When considering mining platform scales in Maysan, bwer company stands out. Known for their top-tier supply and support services, they have established themselves as a reliable partner in the mining industry across Iraq. With an array of high-quality scales and tailored solutions, they meet the unique demands of mining operations in varied environments.

bwer company’s expertise is not only confined to sale but extends to installation and maintenance, ensuring that mining businesses can rely on their equipment for sustainable operations. For more information on their products and services, visit their website at bwer company or contact them via email at info@bwerpipes.com.

FAQs:

What are mining platform scales used for?

They are used to weigh large loads in mining operations, ensuring accurate resource management.

Why are accurate measurements important in mining?

Accurate measurements prevent inventory and financial discrepancies, crucial for logistical efficiency.

How do mining platform scales enhance productivity?

By providing precise data, they minimize errors and optimize resource use, leading to more efficient operation.

What types of mining platform scales are available?

Common types include truck scales for heavy loads and conveyor belt scales for continuous weighing tasks.

What technological advancements are being integrated into these scales?

Automation and IoT capabilities are increasingly incorporated to enhance accuracy and facilitate remote monitoring.

What challenges exist in deploying mining platform scales?

Challenges include initial investment costs, need for regular maintenance, and system integration issues.

How can bwer company assist with mining platform scales?

They provide comprehensive solutions, from supplying and installing scales to offering maintenance services.

Where is bwer company based and how can I contact them?

Based in Iraq, bwer company can be reached via their website at bwer company or by email at info@bwerpipes.com.