In the bustling industrial landscape of Al-Muthanna, the need for accurate and efficient measurement systems is paramount. The industrial Weighbridge platform has emerged as an essential tool for businesses looking to enhance logistical precision and operational efficiency. From transporting goods to verifying their weight accurately, the importance of a reliable Weighbridge platform cannot be overstated. This article delves into the significance of industrial Weighbridge platforms in Al-Muthanna, exploring their benefits, components, providers, and much more.

Understanding the Industrial Weighbridge Platform in Al-Muthanna

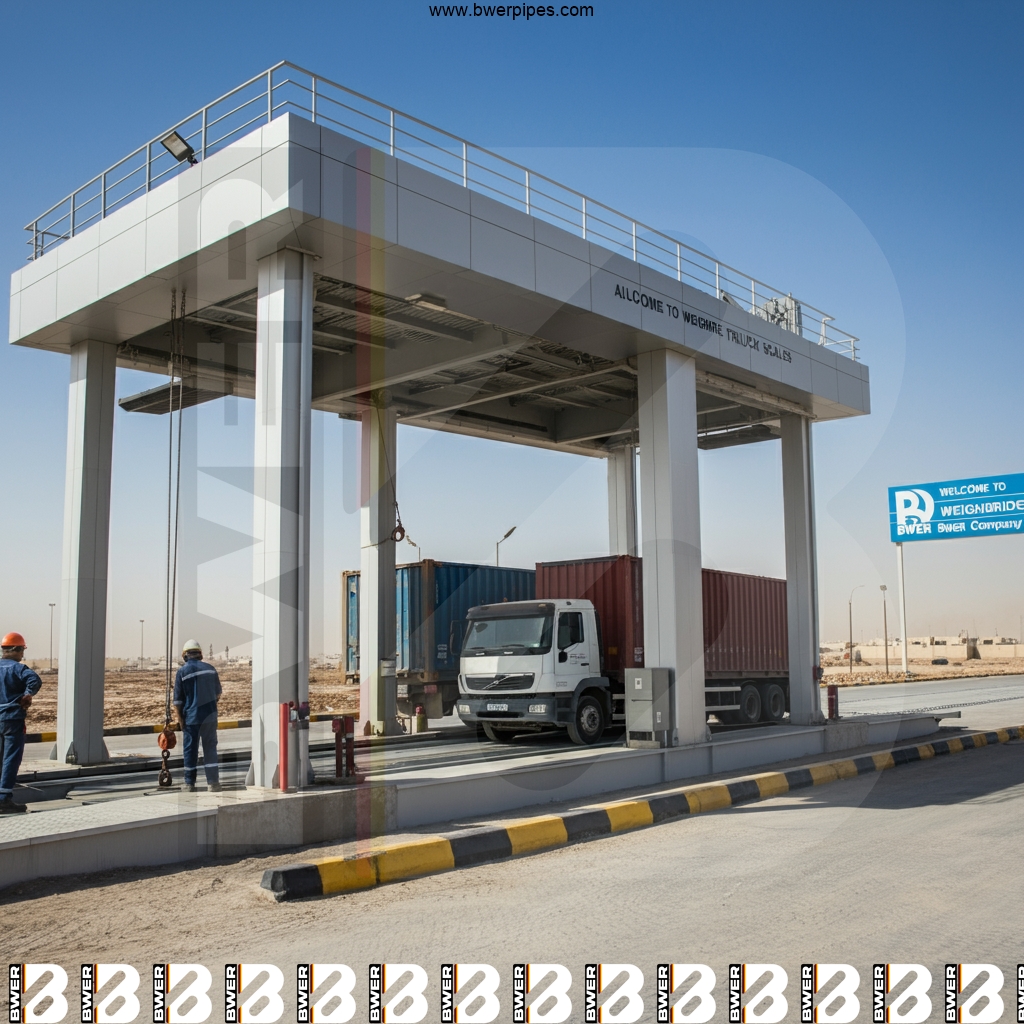

Industrial Weighbridge platforms are indispensable in Al-Muthanna’s thriving industrial sector. These robust structures facilitate the precise weighing of large vehicle loads, contributing significantly to efficient logistics management. Weighbridges serve a vital role in reducing discrepancies in goods transportation, enhancing trade accuracy, and ensuring compliance with industry standards. With the increasing industrial activity in Al-Muthanna, the relevance of these platforms continues to grow, attracting businesses aiming to streamline their operations.

Moreover, Weighbridge platforms are engineered to withstand harsh environmental conditions and heavy loads, making them ideal for industries such as construction, agriculture, and logistics. Technological advancements have introduced digital and automated Weighbridge systems that offer real-time data, further optimizing supply chain management in Al-Muthanna.

Components of an Industrial Weighbridge Platform

A typical industrial Weighbridge platform comprises several key components that ensure its reliable operation. The Weighbridge deck, usually made from steel or concrete, is the primary component on which vehicles are weighed. Its durability determines the platform’s lifespan and its ability to withstand heavy-duty usage. Load cells are another critical element; these sensors convert the force of the load on the platform into an electronic signal, providing accurate weight readings.

Additional components include junction boxes, which consolidate signals from multiple load cells for processing, and Weighbridge indicators, which display the calculated weight. Recently, advanced systems have incorporated features like automated ticketing, remote monitoring, and integration with fleet management systems, greatly enhancing functionality and user convenience.

Benefits of Using Industrial Weighbridge Platforms

Implementing industrial Weighbridge platforms in Al-Muthanna offers numerous advantages. Firstly, they significantly enhance operational efficiency by enabling quick and accurate vehicle load assessments. This reduces check-in and check-out times at industrial sites, leading to improved productivity. Furthermore, accurate weighing helps prevent overloading, which can cause wear and tear on vehicles and infrastructure and result in costly fines.

Weighbridge platforms also contribute to improved inventory management by providing precise data for stock control, helping businesses maintain optimal inventory levels. Additionally, by ensuring compliance with legal weight limits, these platforms help companies avoid penalties and maintain their reputations as reliable suppliers. Environmental sustainability is another benefit, as precise weight management can reduce fuel consumption and carbon emissions.

Implementation Challenges and Solutions

While the benefits of Weighbridge platforms are clear, implementing these systems in Al-Muthanna does present challenges. Infrastructure limitations, such as the availability of suitable installation sites, can pose initial hurdles. Furthermore, maintaining accuracy requires regular calibration and servicing of equipment to avoid potential discrepancies caused by external factors like temperature fluctuations or dust accumulation.

To address these challenges, businesses can work closely with reputable suppliers to ensure proper installation and maintenance of Weighbridges. Investing in high-quality, durable equipment and trained personnel can further mitigate issues, ensuring reliable performance over time. Employing emerging technologies, such as IoT connectivity, can facilitate remote monitoring and diagnostics, simplifying maintenance efforts.

Choosing the Right Industrial Weighbridge Platform

Selecting the appropriate Weighbridge platform for specific industrial needs in Al-Muthanna requires careful consideration. Businesses should evaluate factors such as expected vehicle traffic, load capacity requirements, and the physical characteristics of the installation site. It’s crucial to select a platform that can accommodate the heaviest expected loads while ensuring durability and longevity.

Technology integration is another important factor, with many modern Weighbridges offering advanced features such as automation, data analytics, and integration with enterprise resource planning (ERP) systems. By partnering with experienced suppliers, companies can receive expert guidance in choosing platforms that align with their operational goals and budget constraints, ensuring maximum return on investment.

bwer Company: Leading Supplier of Industrial Weighbridge Platforms in Iraq

In the landscape of industrial Weighbridge platforms in Al-Muthanna, the bwer Company stands out as a leading and reliable supplier. Known for their high-quality products and exceptional service, bwer specializes in delivering tailor-made weighing solutions that meet the diverse needs of industries across Iraq. From installation to maintenance, their comprehensive range of services ensures seamless operation and optimal performance of Weighbridge platforms.

bwer‘s commitment to innovation and customer satisfaction makes them a preferred choice for businesses seeking durable and efficient weighing solutions. For more information, you can visit their website at bwer Company or contact them via email at info@bwerpipes.com.

FAQs:

What is an industrial Weighbridge platform?

An industrial Weighbridge platform is a large weighing device used to weigh vehicles and their contents, essential for managing logistics in industrial settings.

How does a Weighbridge work?

A Weighbridge utilizes load cells to convert the weight of a vehicle into an electronic signal, which is then processed and displayed for record-keeping and analysis.

Why are Weighbridges important in Al-Muthanna?

Weighbridges are crucial in Al-Muthanna for ensuring accurate weight measurement of goods, optimizing logistics, and maintaining compliance with transportation regulations.

What are the key components of a Weighbridge platform?

Main components of a Weighbridge platform include the deck, load cells, junction boxes, and Weighbridge indicators.

What are the benefits of using a Weighbridge?

Benefits include enhanced operational efficiency, improved inventory management, prevention of overloading, and compliance with legal regulations.

What challenges might arise during the implementation of a Weighbridge platform?

Challenges can include infrastructure limitations, maintenance requirements, and ensuring accuracy through regular calibration and servicing.

How can businesses select the right Weighbridge platform?

Businesses should consider vehicle traffic, load capacity, site suitability, and technology features, seeking expert guidance from suppliers like bwer Company.

Why choose bwer Company for Weighbridge solutions?

bwer Company offers high-quality, customized weighing solutions with excellent support services, making them a leading supplier in the industrial weighing sector.