Industrial Weighbridges play a crucial role in the economic infrastructure of Mosul, facilitating accurate and consistent weight measurement for various industries, including construction, agriculture, and logistics. An industrial Weighbridge in Mosul ensures operational efficiency and compliance with legal standards, boosting productivity and economic growth. As businesses continue to expand their operations in Mosul, having access to high-quality Weighbridge solutions is more important than ever. This article will delve into the intricacies of industrial Weighbridges in Mosul, highlighting their importance and the leading suppliers in the region.

The Importance of Industrial Weighbridge in Mosul

Industrial Weighbridges in Mosul are pivotal in maintaining accurate weight measurement, essential for ensuring that transportation stays within legal limits and maximizes load efficiency. Whether for agricultural products, construction materials, or other heavy goods, Weighbridges help businesses maintain productivity and profitability by ensuring precision in weight calculation.

Furthermore, with the increasing focus on legal compliance and safety regulations, industrial Weighbridges serve as an indispensable tool in avoiding penalties and operational disruptions. Investing in a Weighbridge guarantees the integrity of transactions, fosters trust with business partners, and enhances a company’s reputation in the competitive Mosul market.

Types of Industrial Weighbridge Solutions in Mosul

In Mosul, various types of industrial Weighbridges are available, each designed to cater to specific industry needs. Above-ground Weighbridges are a popular choice due to their straightforward installation and adaptability to various resources. These typically require a ramp for vehicle access and are suitable for businesses with space availability.

In contrast, pit-mounted Weighbridges offer an efficient solution for locations with limited space, as vehicles can run over the Weighbridge without a ramp. This design is highly advantageous in urban areas like Mosul, where maximizing space utilization is crucial. Each Weighbridge type offers unique benefits, allowing businesses to choose based on their operational requirements and site conditions.

Technological Advancements in Industrial Weighbridge Systems

Modern industrial Weighbridges in Mosul are equipped with advanced technologies that enhance accuracy, reliability, and data management. Digital load cells, for example, provide precise measurements and are less susceptible to environmental factors, ensuring consistent performance over time.

Many Weighbridge systems now integrate software solutions for real-time data collection and analysis, offering comprehensive weight data management. This technological advancement supports business decision-making processes, helping companies streamline operations, monitor efficiency, and ensure accountability. The integration of remote monitoring capabilities also allows for better maintenance scheduling and cost management.

Choosing the Right Industrial Weighbridge Vendor in Mosul

Selecting the right supplier for an industrial Weighbridge in Mosul is critical for achieving long-term operational success. Factors to consider include the vendor’s industry experience, technical support, and the quality of the Weighbridge products offered. Conducting thorough research and seeking recommendations can significantly aid in making an informed decision.

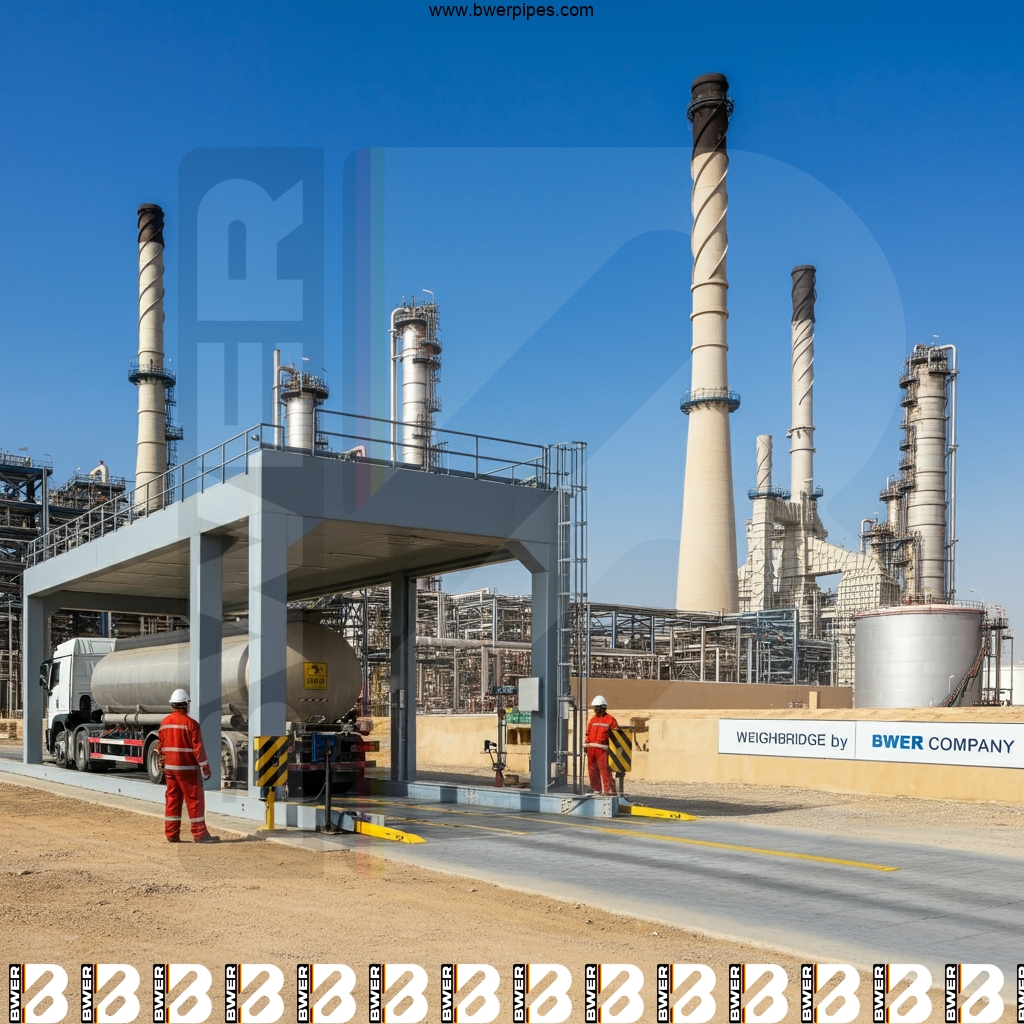

bwer Company stands out as a leading and reliable supplier in Iraq, offering top-tier industrial Weighbridge solutions tailored to the unique needs of its clientele. With years of experience and a deep understanding of the local market’s demands, bwer ensures the delivery of superior weighing solutions coupled with excellent after-sales service and support.

Installation and Maintenance of Industrial Weighbridges

Proper installation and regular maintenance are vital for the longevity and performance of an industrial Weighbridge in Mosul. Skilled technicians should oversee the installation process to ensure that the setup meets industry standards and local regulations, minimizing operational risks.

Routine maintenance, including calibration and inspections, prevents mechanical failures and ensures accuracy and reliability. Engaging with a reputable supplier that provides comprehensive maintenance services can significantly extend the lifespan of a Weighbridge, safeguarding the business’s investment and operational continuity.

bwer Company: Leading Supplier of Industrial Weighbridge in Mosul

As a trusted name in Iraq, bwer Company leads in providing high-quality industrial Weighbridge solutions in Mosul and the wider region. bwer’s commitment to excellence is evident in their comprehensive range of products and customer-focused services. Their portfolio includes various modern Weighbridge solutions equipped with cutting-edge technology to suit diverse industrial needs. To learn more about bwer‘s offerings, please visit their website bwer company or contact them via email at info@bwerpipes.com.

FAQs:

What is an industrial Weighbridge?

An industrial Weighbridge is a large-scale weighing device used to measure the weight of vehicles and their contents, essential for industries like transport, construction, and agriculture.

Why are Weighbridges important in Mosul?

They ensure accurate weight measurement, legal compliance, and operational efficiency, vital for businesses relying on precise load data.

What types of Weighbridges are available in Mosul?

Common types include above-ground and pit-mounted Weighbridges, each offering different benefits based on space availability and operational needs.

How do Weighbridges improve logistics operations?

By providing precise weight data, they help optimize load management, reduce overloading risks, and ensure road safety compliance.

What technological features are available in modern Weighbridges?

Advanced features include digital load cells, integration with data management software, and remote monitoring capabilities.

How frequently should Weighbridge maintenance be performed?

Regular maintenance should be conducted based on usage frequency and environmental conditions, typically every six months to annually.

Why choose bwer Company for Weighbridge solutions?

bwer is a leading supplier with a reputation for high-quality products and outstanding customer service in industrial Weighbridge solutions in Mosul.

How can businesses contact bwer Company for their services?

Interested businesses can visit bwer company’s website or email them at info@bwerpipes.com for more information and inquiries.