Understanding how Weighbridges work is essential for numerous industries, especially for Iraqi businesses involved in transportation, logistics, and manufacturing. Weighbridges are crucial tools for accurately measuring the weight of vehicles and goods, ensuring compliance with regulations and optimizing operations. In this comprehensive guide, we will delve into the workings of Weighbridges, highlighting their significance for businesses in Iraq and how they can enhance efficiency across various sectors.

What is a Weighbridge and How Does it Function?

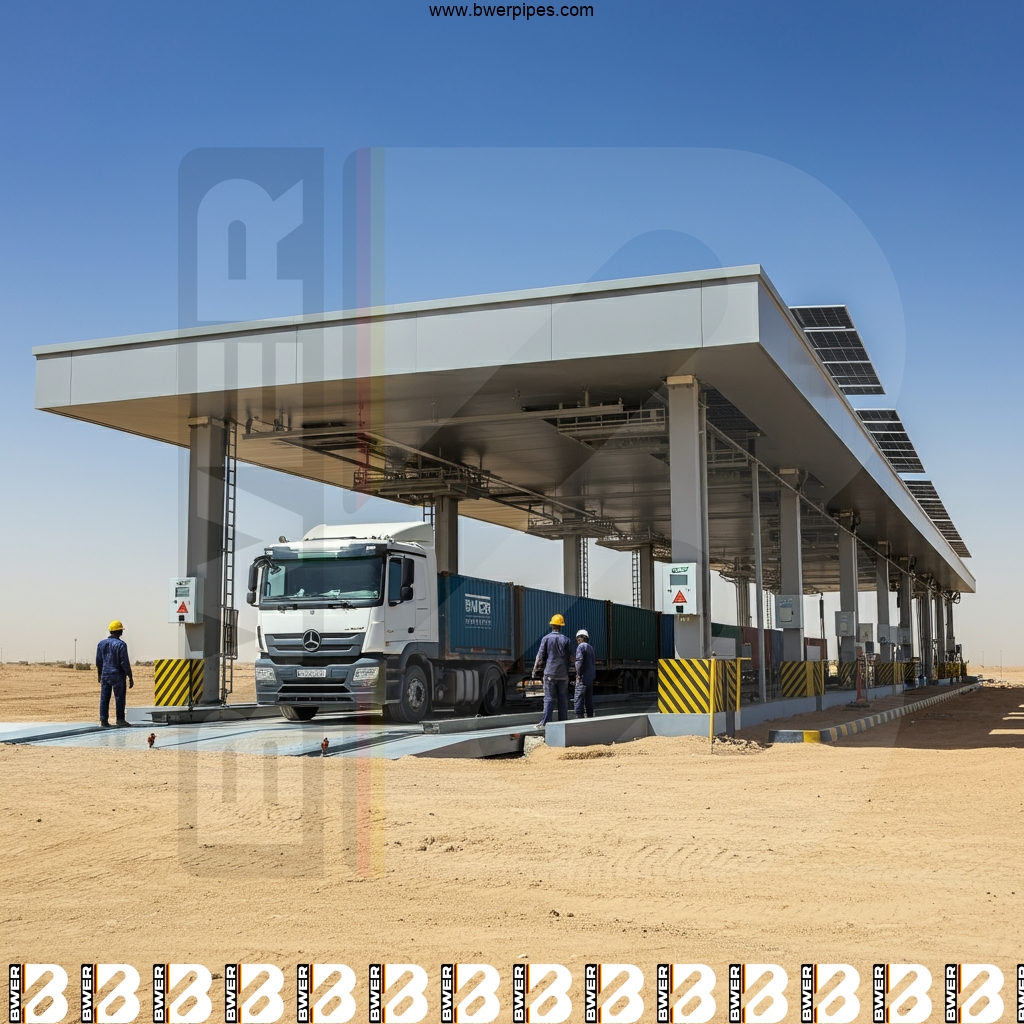

A Weighbridge, also known as a truck scale, is a large set of scales, usually mounted permanently on a concrete foundation, to weigh entire rail or road vehicles and their contents. The key to a Weighbridge‘s function is its ability to provide an accurate measurement of a vehicle’s gross weight by calculating the difference between the vehicle’s mass when empty and when loaded. This is achieved through an arrangement of multiple load cells that accurately measure the weight of the vehicle as it rests on the bridge.

The process begins as a vehicle drives onto the Weighbridge, positioning itself so that its wheels are entirely supported by the bridge’s platform. The load cells installed beneath the platform measure the downward force imposed by the vehicle’s weight and convert it into a readable measurement. For Iraqi businesses, understanding how to operate a Weighbridge efficiently can lead to better load management and compliance with legal weight limits, thereby reducing risks and optimizing supply chain operations.

The Importance of Weighbridges for Iraqi Businesses

Weighbridges are pivotal for businesses in Iraq for several reasons. Firstly, by ensuring accurate weight measurement, they help companies avoid overloading penalties and adhere to national and international transportation regulations. This compliance is crucial for maintaining a good reputation and avoiding costly fines. Secondly, Weighbridges enable businesses to maintain load consistency, leading to better customer satisfaction and improved business performance.

Additionally, Weighbridges can play a vital role in inventory management. By providing precise data on product delivery and dispatch, Iraqi businesses can leverage this information to monitor inventory movements meticulously. This ensures efficient resource utilization and minimizes wastage, which is particularly beneficial in industries such as agriculture, construction, and mining.

Types of Weighbridges Suitable for Iraqi Markets

In Iraq, businesses can choose from various types of Weighbridges based on their specific operational needs. Portable Weighbridges are favored for their flexibility; they can be moved from site to site with minimal setup time, making them ideal for businesses that require versatility. On the other hand, pit-mounted Weighbridges, which are installed at ground level, offer a permanent solution with high durability, suited for locations with high traffic volumes.

Additionally, surface-mounted Weighbridges are another option, where the installation is above ground with ramps for vehicle access. These require less site preparation and are easier to install and maintain. Each type of Weighbridge has its own set of advantages and selecting the right one can significantly impact business efficiency. Leading suppliers like bwer company can provide expert guidance to Iraqi businesses in choosing the best Weighbridge solution for their operational needs.

How to Ensure Accurate Weighing and Compliance

To ensure accurate weighing and compliance with local and international standards, businesses need to undertake a few critical steps. Regular calibration and maintenance of the Weighbridge are essential to maintain its accuracy. Calibration involves verifying the Weighbridge‘s readings against known weight standards and adjusting it as necessary. This should be carried out periodically and by professionals for optimal results.

Another important aspect is the training of staff in operating the Weighbridge, ensuring that they are familiar with both the equipment and the software used to record and analyze data. Proper training minimizes human error and guarantees consistent, accurate measurements. Partnering with well-established companies like bwer company can ensure that Iraqi businesses receive comprehensive support and service for Weighbridge operations.

Steps to Integrate Weighbridge Data into Business Operations

Integrating Weighbridge data into the broader aspects of business operations can offer significant advantages. Firstly, implementing an automated data collection system can simplify the process, reducing paperwork and the risk of human error. This can be achieved by using integrated software solutions that directly input Weighbridge data into the company’s existing management systems.

Moreover, real-time data analysis and reporting can aid in quick decision-making. By having immediate access to weighing data, businesses can make informed decisions regarding inventory management, logistics planning, and load optimization. This integration can facilitate smoother operations and lead to improved business efficiency and productivity.

bwer Company: Your Trusted Weighbridge Supplier in Iraq

When it comes to investing in Weighbridges, bwer company stands as a leading and reliable supplier in Iraq. With a comprehensive range of Weighbridge solutions coupled with unmatched expertise, bwer company offers Iraqi businesses the quality and support they need to succeed. Whether you are looking for portable solutions or permanent installations, bwer company has the products and the experience to meet your business’s demands. For more information on their products and services, you can visit their website or reach out via email at info@bwerpipes.com.

FAQs:

What types of vehicles can be weighed on a Weighbridge?

Weighbridges are capable of weighing a variety of vehicles ranging from small vans and pickups to large trucks and multi-trailer rigs, depending on their capacity.

How often should a Weighbridge be calibrated?

It’s recommended to calibrate a Weighbridge at least annually, or more frequently if it is subject to heavy use, to ensure continued accuracy.

What factors can affect the accuracy of Weighbridge measurements?

Factors such as environmental conditions, debris accumulation, and equipment wear and tear can affect accuracy, making maintenance crucial.

Can Weighbridges integrate with existing business systems?

Yes, modern Weighbridges often come with software that can integrate with a company’s current systems, facilitating data management and analysis.

What should be considered when selecting a Weighbridge supplier?

Businesses should consider factors such as product quality, supplier expertise, after-sales support, and the ability to provide customized solutions.

Are there specific regulations for Weighbridges in Iraq?

Yes, there are regulations in place to ensure safety and compliance, which vary by industry and government standards. Consulting with local authorities or experts is advised.

How can businesses ensure efficient Weighbridge operation?

Training staff, implementing regular maintenance schedules, and integrating advanced software solutions are key steps for efficient operation.

What are the maintenance requirements for a Weighbridge?

Regular cleaning, routine inspections, timely repairs, and calibration are necessary to keep a Weighbridge functioning effectively.