Constructing a Weighbridge in Qadisiyah represents a significant advancement for the region’s infrastructure, aiding the construction and transportation industries in managing heavy loads precisely. Understanding the utility and function of a construction Weighbridge is essential for businesses involved in these sectors. This article offers a detailed exploration of construction Weighbridges in Qadisiyah, focusing on key elements and highlighting the role of bwer Company as a pivotal player in this industry within Iraq. Read on to discover why construction Weighbridges are indispensable and how you can leverage them for enhanced operational efficiency.

Understanding Construction Weighbridge in Qadisiyah

Construction Weighbridges are essential for accurately measuring the weight of construction vehicles, ensuring compliance with safety standards and regulations. In Qadisiyah, these Weighbridges are particularly crucial due to the region’s active construction and development activities. They provide businesses with the reliability and accuracy needed to manage heavy loads effortlessly. As construction processes grow in scale and complexity, utilizing a Weighbridge becomes indispensable for operational success and safety.

Employing a Weighbridge in Qadisiyah allows companies to keep meticulous records of weight transactions, which is vital for maintaining efficiency and accountability. These structures are not just practical but also technologically advanced, often integrated with digital monitoring and computer systems, enhancing the precision and usability in the construction sector.

Features of a Construction Weighbridge in Qadisiyah

Weighbridges designed for construction in Qadisiyah are equipped with a variety of features that enhance functionality and reliability. A standard Weighbridge system here will include robust platforms capable of withstanding extreme loads, ensuring they can manage heavy-duty construction vehicles without compromising structural integrity. Durability is a key consideration, given the demanding environment and heavy usage.

These Weighbridges often incorporate advanced software solutions that enable real-time data tracking and reporting. This integration is crucial for logistics management, providing an invaluable tool for construction managers to oversee operations efficiently. Furthermore, high-tech interfaces simplify the user experience, reducing the risk of human error in manual data recording.

Installation and Maintenance of Construction Weighbridge in Qadisiyah

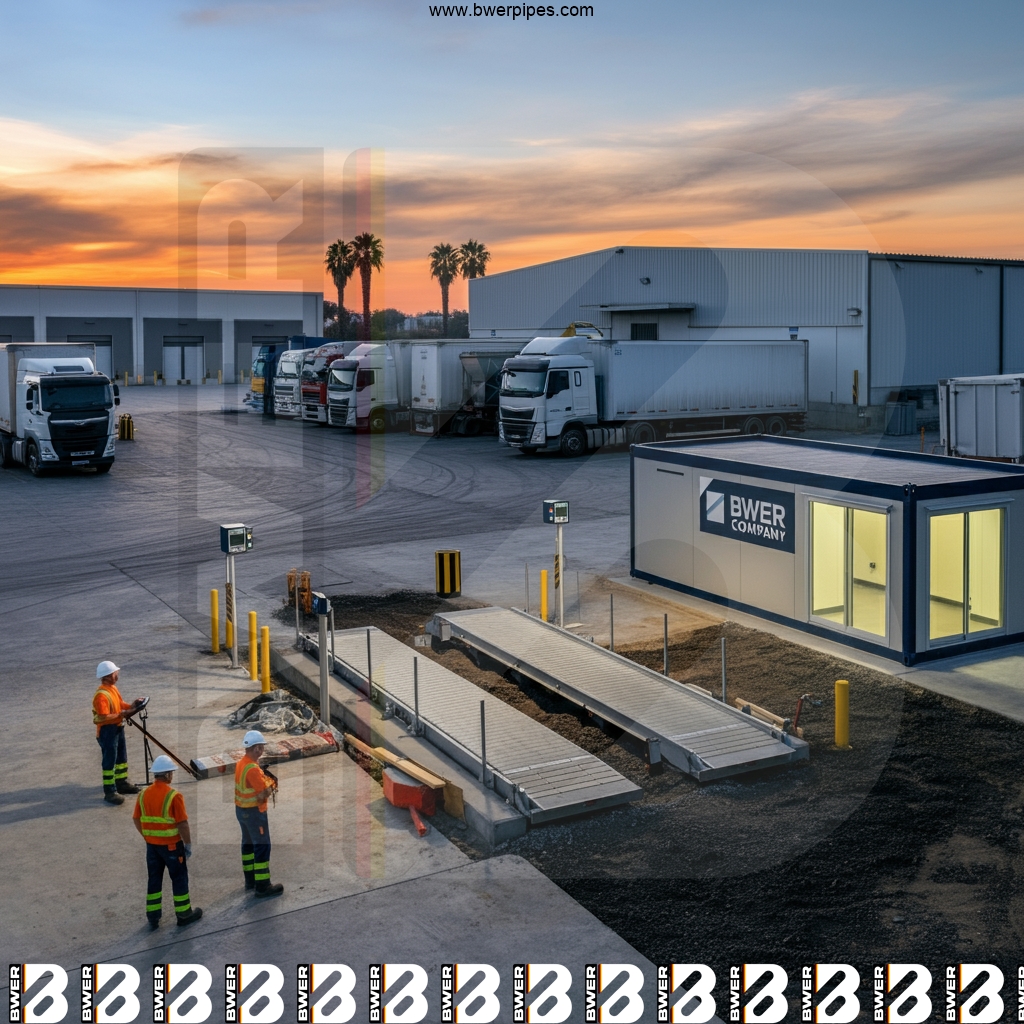

The installation process of a construction Weighbridge in Qadisiyah necessitates meticulous planning and execution to guarantee optimal performance. Site selection is critical, emphasizing accessibility and stability to support the Weighbridge’s extensive use. The installation team typically includes experts who ensure that the setup meets local regulations and industrial standards.

Routine maintenance of the Weighbridge is vital to sustain its functionality and extend its lifespan. Engage with professional service providers to conduct regular inspections and calibrations, maintaining accuracy and preventing any mechanical issues that could disrupt operation. Maintenance contracts often include emergency support services, ensuring minimal downtime during unexpected breakdowns.

Economic Impact of Construction Weighbridge in Qadisiyah

The incorporation of Weighbridges in Qadisiyah contributes significantly to the local economy by fostering a more efficient construction industry. These Weighbridges facilitate faster and safer movement of construction materials, thereby increasing productivity and reducing project completion times. This efficiency in turn can lead to cost savings, enhancing profitability for construction companies.

On a broader scale, Weighbridges play a vital role in regulatory compliance, reducing risks associated with overloading on roads which can lead to infrastructure damage. This protection of public assets helps in conserving municipal budgets which can then be redirected to other developmental initiatives, thereby stimulating the local economy and offering broader societal benefits.

Technological Advancements in Construction Weighbridge in Qadisiyah

Recent technological progressions have significantly enhanced the capabilities of construction Weighbridges in Qadisiyah. Many systems now integrate IoT solutions that provide seamless connectivity for remote monitoring and data management. This integration allows for predictive maintenance, alerting operators to potential issues before they become critical, and optimizing operational efficiency.

Automation in Weighbridge operations is another advanced feature gaining traction. Automatic Vehicle Identification (AVI) systems streamline vehicle processing by eliminating the need for manual entry, thus enhancing throughput in busy construction sites. Moreover, data analytics derived from Weighbridge operations can offer insights that drive tactical decisions from inventory management to logistical planning.

bwer Company: Leading Supplier of Construction Weighbridges in Qadisiyah

bwer Company stands out as a leading supplier of construction Weighbridges in Iraq, providing premium products and services that meet the demanding needs of the construction sector in Qadisiyah. With a commitment to quality and customer satisfaction, bwer Company offers innovative weighing solutions tailored to enhance operational efficiency and accuracy. Their expertise in technology integration makes them a reliable partner for businesses aiming to optimize their Weighbridge systems. For more information about their products and services, visit [bwer company](https://bwerpipes.com/) or contact them via email at info@bwerpipes.com.

FAQs

What is a construction Weighbridge?

A construction Weighbridge is a large, usually heavy-duty platform used to measure the weight of vehicles and their contents in construction sites.

Why are Weighbridges important in construction?

Weighbridges ensure the accurate measurement of loads, help maintain compliance with safety and weight regulations, and enhance logistical efficiency.

What features should I look for in a Weighbridge?

Durability, technology integration for data management, and user-friendly interfaces are key features to look for in a Weighbridge.

How often should a Weighbridge be maintained?

Regular maintenance, including calibration and inspections, should occur at least once a year, or more frequently if the Weighbridge is heavily used.

Can Weighbridges be automated?

Yes, modern Weighbridges can incorporate automation features such as Automatic Vehicle Identification (AVI) to improve efficiency.

How do Weighbridges benefit the local economy?

By improving workflow efficiency and ensuring regulatory compliance, Weighbridges help reduce costs and protect public infrastructure, positively impacting the local economy.

What is the cost range for installing a Weighbridge in Qadisiyah?

Installation costs can vary depending on size, features, and technology integration but generally start from several thousand dollars.

Why choose bwer Company for Weighbridge solutions?

With their expertise in technology and commitment to quality, bwer Company provides tailored, efficient Weighbridge solutions that stand out in the market.