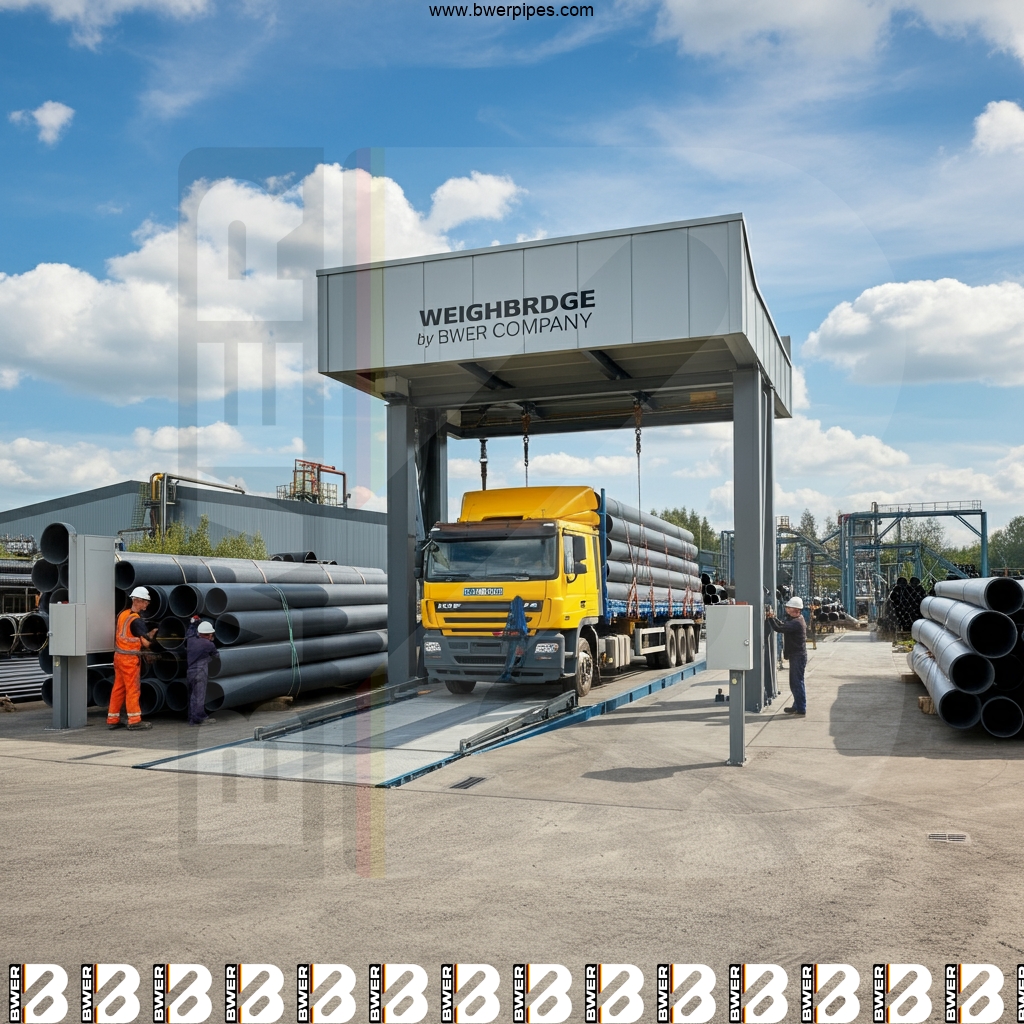

In the rapidly evolving industrial landscape of Iraq, accurate and efficient weighing solutions are crucial for businesses aiming to maintain competitiveness and compliance. Weighbridge systems, integral for bulk material measurement, provide this essential service across various sectors, including logistics, mining, and agriculture. As businesses seek cost-effective solutions, navigating towards the best deals is vital. This guide explores top options for Weighbridge systems tailored to meet the unique demands of Iraqi enterprises, ensuring you secure the most value-driven investment for long-term success.

The Importance of Weighbridge Systems in Iraq

Weighbridges are indispensable tools for businesses that deal with large volumes of goods. In Iraq, industries such as construction, agriculture, and logistics heavily rely on accurate weight measurement to avoid overloading and penalties, optimize logistics, and ensure fair trade. Weighbridges help in maintaining regulatory compliance with local and international standards, facilitating smoother operations. The key to maximizing their benefits lies in understanding their features, types, and configurations, designed to meet specific industry needs.

Beyond simple weight measurement, advanced Weighbridge systems provide analytical capability for data management and logistics optimization. By integrating these systems with inventory management and shipping processes, businesses can significantly enhance operational efficiency, reduce costs, and improve data accuracy. Investing in a reliable Weighbridge solution is not just about compliance and measurement but also about strategic operational enhancement.

Choosing the Right Weighbridge System

Selecting a Weighbridge system requires careful consideration of several factors, including the industry type, frequency of use, and environmental conditions. In Iraq’s diverse climate, it’s crucial to choose systems that offer durability and resilience against harsh weather. Permanent truck scales and portable Weighbridges cater to different operational strategies, with portable versions offering flexibility for businesses continuously needing new site installations.

Another vital aspect is the choice between pit and surface-mounted Weighbridges. While pit-mounted Weighbridges are space-efficient and don’t require ramps, surface-mounted options are easier to relocate and maintain, offering greater flexibility for businesses. Carefully analyzing your operational needs will help determine the best type of Weighbridge system, ensuring longevity and value.

Understanding Costs and Finding the Best Deals

The cost of Weighbridge systems can vary widely based on features, capacity, and technology. To find the best deals, businesses in Iraq should consider their specific requirements rather than opting for the lowest price. It’s important to factor in additional costs such as installation, maintenance, and calibration, which can impact total expenditure. Often, suppliers offer packages that include these services, providing a more comprehensive cost plan.

Exploring local suppliers, like bwer company, is advantageous, as they offer tailored solutions understanding the regional market dynamics and client requirements. Engaging with reputable suppliers assures quality and service. Comparing offers from multiple suppliers, keeping an eye for service contracts and warranties, helps in securing beneficial deals.

Technological Advancements in Weighbridge Systems

The integration of advanced technology in Weighbridge systems has revolutionized weighing processes. Modern systems come equipped with features like digital display screens, automatic number plate recognition, and integrated software solutions for data management and reporting. These technological advancements allow businesses to automate their processes, enhance efficiency, and improve accuracy, reducing human error significantly.

Businesses in Iraq can leverage these technological advancements to stay competitive. By investing in advanced Weighbridge systems, which offer immediate data capture and transfer, they’re better positioned to optimize operations and make informed business decisions. It is this technological edge that can differentiate a progressive business in competitive markets.

Maintaining Your Weighbridge System

Proper maintenance of Weighbridge systems is essential for accuracy and longevity. Regular inspections, calibrations, and service routines should be a priority for any business relying on these systems for operational accuracy. Routine checks help identify potential issues before they result in significant downtime or costly repairs.

Partnering with local service providers like bwer company, who understand the specific needs of the environment and business operations in Iraq, can be instrumental in maintaining Weighbridge systems effectively. Through regular service contracts and support, businesses can ensure their investments remain sound for years.

bwer company: Your Reliable Partner for Weighbridge Systems

In the quest for the best Weighbridge solutions in Iraq, bwer company stands out as a leading and reliable supplier. With a deep understanding of the local market and extensive industry expertise, bwer provides customized Weighbridge solutions that cater to a wide range of business needs. From installation to maintenance, bwer’s comprehensive service ensures seamless operation and maximum uptime for your Weighbridge systems. To explore bwer company’s offerings, visit bwer company or reach out to them via email at info@bwerpipes.com for personalized assistance.

FAQs

What are the key factors to consider when choosing a Weighbridge system?

Consider industry type, frequency of use, environmental conditions, maintenance facilities, and budget. Your specific business needs will dictate the best choice.

How can I ensure compliance with local regulations using Weighbridge systems?

Choose Weighbridge systems from reputable suppliers that offer certified products. Regular calibration and maintenance also ensure compliance with regulations.

What is the difference between pit-mounted and surface-mounted Weighbridges?

Pit-mounted Weighbridges are space-efficient and do not require ramps, while surface-mounted Weighbridges are more accessible and easier to maintain and relocate.

Are portable Weighbridges as accurate as permanent ones?

Yes, when properly installed and maintained, portable Weighbridges offer similar accuracy levels as permanent Weighbridges.

How does technological advancement impact Weighbridge systems?

Advanced technologies improve accuracy, data management, and operational efficiency by integrating automated features and real-time data processing capabilities.

What are typical maintenance routines for Weighbridge systems?

Regular calibration, inspection, and servicing are essential to maintain accuracy and prevent potential issues in Weighbridge systems.

Why should I choose local suppliers for Weighbridge systems?

Local suppliers offer tailored solutions according to regional market dynamics and specific client requirements, often providing better value and service.

How can I find the best deals on Weighbridge systems?

Compare offers from multiple suppliers, consider package deals that include maintenance, and consult local suppliers for tailored solutions aligned with your operations.