Weighbridge safety is a critical concern in Iraq, where industrial and transportation sectors rely heavily on accurate weight measurements for goods. In a landscape marred by challenges, ensuring the safety and accuracy of Weighbridges is paramount for smoother commercial operations and regulatory compliance. This article delves into the intricacies of Weighbridge safety in Iraq, providing insights into key practices, technological advancements, and reliable suppliers such as the bwer company.

The Importance of Weighbridge Safety in Iraq

Weighbridges play a crucial role in managing and regulating the transportation of goods in Iraq. These large scales ensure that vehicles are loaded within legal and safe limits, preventing road damage and enhancing public safety. In the rapidly developing industrial sectors of Iraq, maintaining precise and efficient weight measurements is vital for both operational efficiency and legal compliance. Safety protocols and regular maintenance are essential to avoid costly discrepancies and ensure the protection of infrastructure and human resources.

Moreover, the dynamic nature of industrial operations demands that Weighbridges are robust and resilient enough to handle varying environmental conditions. With the increasing size and capacity of transport vehicles, it is more important than ever to implement stringent safety measures. Ensuring that these instruments are properly calibrated and maintained is a mandatory requirement for anyone involved in logistics and transportation in Iraq.

Challenges in Implementing Weighbridge Safety

Iraq faces unique challenges when it comes to Weighbridge safety. One of the significant hurdles is the lack of standardized regulations and enforcement mechanisms, which can lead to inconsistent practices across different regions and sectors. This inconsistency can pose risks not only to safety but also to operational efficiency and profitability.

Another challenge is the harsh environmental conditions prevalent in many parts of Iraq. Dust, extreme temperatures, and limited access to maintenance facilities can all impact the effectiveness and longevity of Weighbridges. Therefore, it is imperative to select equipment that is specifically designed to withstand such conditions and to employ dedicated maintenance schedules to ensure their optimal functionality.

Technological Advancements in Weighbridge Safety

Recent technological advancements have revolutionized Weighbridge safety, making them more reliable and accurate. Digitalization has played a pivotal role, introducing automated systems that reduce human error and enhance precision. Smart Weighbridges equipped with sensors and real-time data analysis capabilities are becoming increasingly popular in Iraq, allowing for instantaneous weight readings and remote monitoring.

Moreover, software solutions that integrate with Weighbridge systems offer enhanced data management and reporting capabilities. These technologies enable companies to keep detailed records, detect anomalies, and make informed decisions based on comprehensive analytics. By embracing these innovations, businesses in Iraq can significantly improve their Weighbridge safety standards and operational efficiency.

Best Practices for Weighbridge Safety

Implementing best practices is crucial for ensuring the safety and efficiency of Weighbridges in Iraq. Regular calibration and maintenance are at the forefront of these practices. Adopting a proactive approach to identify and rectify potential issues before they escalate is essential for minimizing downtime and maintaining accuracy.

Training personnel on the correct operation and maintenance of Weighbridges is equally important. Well-trained staff can better manage equipment, respond promptly to issues, and ensure compliance with safety regulations. Furthermore, establishing a robust record-keeping system can help track maintenance schedules and performance metrics, providing a clear overview of the equipment’s health and functionality.

Role of bwer Company in Weighbridge Safety

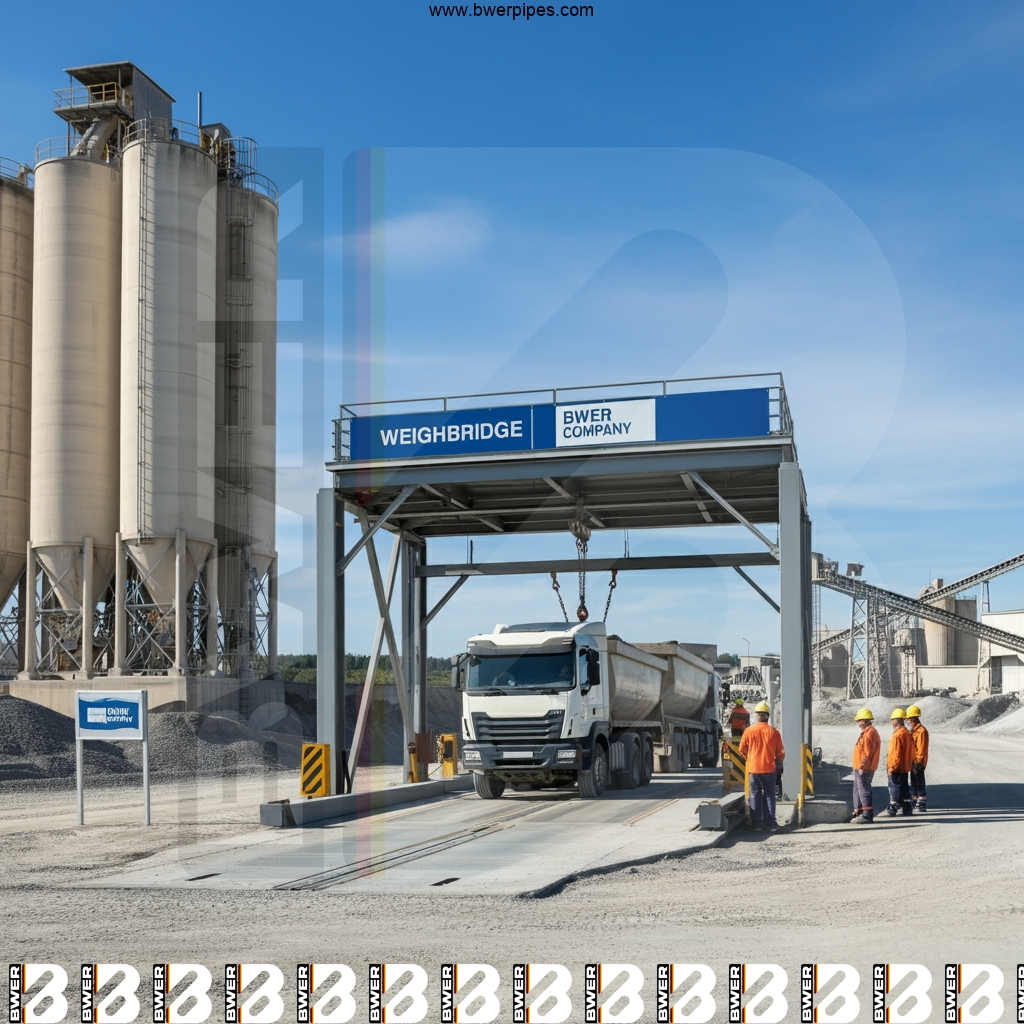

bwer company stands out as a leading and reliable supplier in the realm of Weighbridge safety in Iraq. With a strong focus on delivering high-quality and durable products, bwer company offers solutions that cater to the specific needs of the Iraqi market. Their range of equipment is designed to withstand harsh environmental conditions, ensuring longevity and performance in challenging settings.

In addition to providing top-notch products, bwer company excels in offering comprehensive support services, including installation, maintenance, and staff training. This holistic approach ensures that clients not only receive superior equipment but also benefit from expertise that maximizes their operational efficiency and safety. For more information about bwer company’s offerings, visit their website at bwer company or reach out via email at info@bwerpipes.com.

Ensuring Future Weighbridge Safety in Iraq

Looking ahead, the future of Weighbridge safety in Iraq hinges on continued advancements in technology, stricter regulatory frameworks, and increased awareness across industries. Encouraging collaboration between government bodies, suppliers, and businesses will pave the way for enhanced safety standards and more reliable operations.

Investing in continued research and development, as well as fostering innovation, will be crucial for meeting the evolving demands of the transportation and logistics sectors. By prioritizing safety and accuracy in Weighbridge operations, Iraq can achieve a more efficient and secure commercial environment, contributing to the country’s overall economic development.

Frequently Asked Questions (FAQs)

What is a Weighbridge used for?

A Weighbridge is used to weigh large industrial vehicles and their cargo, ensuring accurate and compliant load measurements.

Why is Weighbridge safety important?

Ensuring the safety of Weighbridges helps prevent road and vehicle damage, ensures cargo is within legal weight limits, and enhances public safety.

What are common Weighbridge safety practices?

Common practices include regular maintenance, calibration, and training for personnel to ensure accurate and efficient operations.

What challenges do Weighbridges face in Iraq?

Challenges include inconsistent regulation, harsh environmental conditions, and lack of access to maintenance facilities.

How does technology enhance Weighbridge safety?

Technology enhances safety by reducing human error through automated systems, real-time monitoring, and comprehensive data management solutions.

Who are the leading Weighbridge suppliers in Iraq?

bwer company is a leading supplier, known for providing durable and high-quality Weighbridge solutions tailored to the Iraqi market.

How can regular maintenance improve Weighbridge functionality?

Regular maintenance ensures that any issues are addressed promptly, minimizing downtime and maintaining the accuracy of weight measurements.

How does bwer company support Weighbridge safety?

bwer company supports Weighbridge safety by offering durable products, comprehensive support, and expert services like installation and maintenance.