Weighbridges play a crucial role in Mosul’s thriving logistics and transportation sector. These vital infrastructures are essential for accurately weighing large vehicles, providing critical data for transport management, ensuring safety, and optimizing operational efficiency. As the city continues to rebuild and expand, the demand for reliable and precise Weighbridge solutions has surged, making it a key focus for businesses and local authorities. In this article, we delve into the intricacies of Weighbridges in Mosul, providing a detailed look at their significance, types, operations, and reliable suppliers like bwer company in Iraq.

Understanding the Importance of Weighbridge in Mosul

Weighbridges are integral to the logistics network, serving as the backbone for accurate vehicle weight measurement. This is particularly important in Mosul, where industries heavily rely on bulk transportation of goods. Weighbridges ensure compliance with legal weight limits, preventing overloading that can cause infrastructure damage and accidents. Besides safety and regulatory compliance, they also enhance efficiency by offering precise measurements that help in planning and allocating resources effectively.

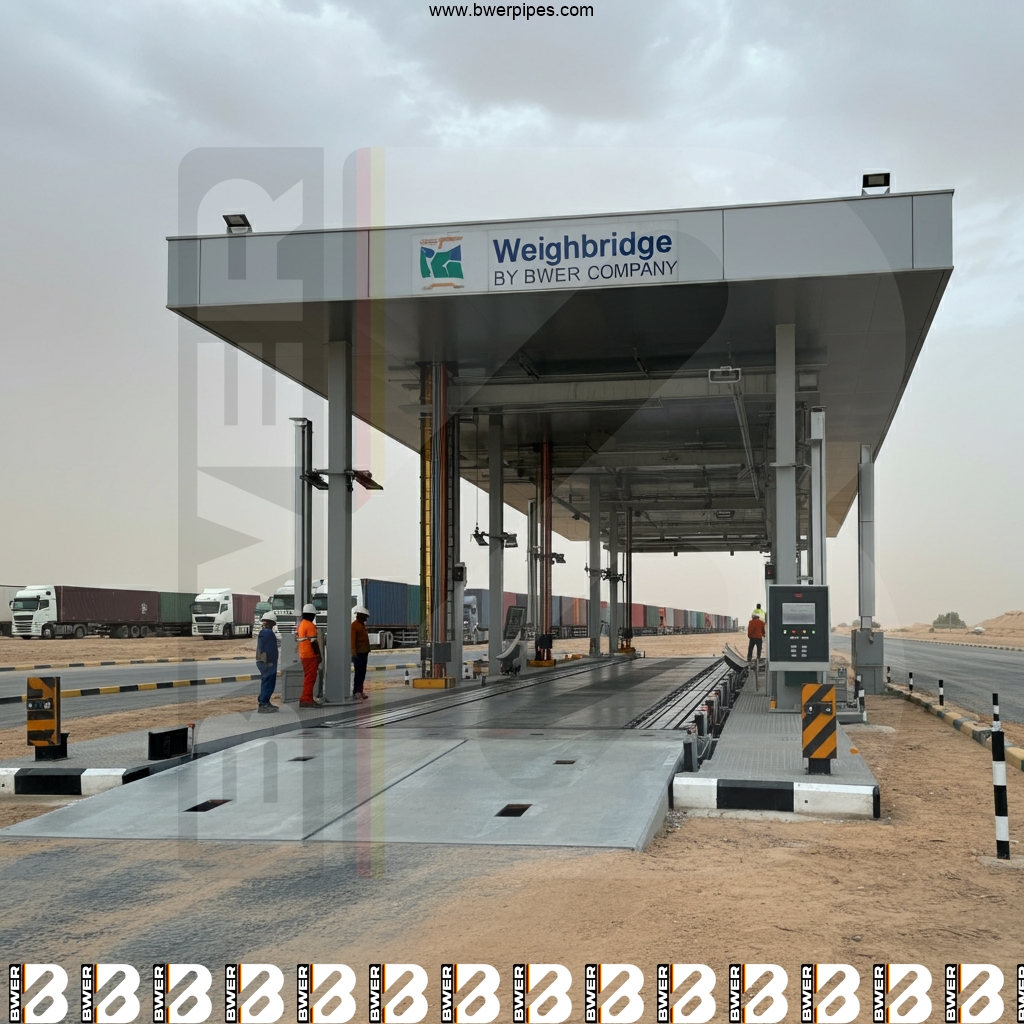

In Mosul, Weighbridges are strategically positioned at various entry and exit points of the city, facilitating seamless movement of goods. This strategic placement aids in logistical planning and reduces bottlenecks at critical junctures, thereby fostering smooth economic activities. As Mosul continues to modernize, the integration of advanced Weighbridge technology is becoming more prevalent, emphasizing accuracy and reliability in load management.

Types of Weighbridges Available in Mosul

Mosul offers a range of Weighbridge types catering to various industrial needs. The most common types include pit-mounted and surface-mounted Weighbridges. Pit-mounted Weighbridges are installed at ground level and do not require ramps, which makes them suitable for areas with space constraints. These are widely used in urban settings within Mosul due to their minimal footprint.

In contrast, surface-mounted Weighbridges require approach ramps, making them ideal for sites with ample space. They are easier to maintain and install, often preferred in rural and industrial outskirts of Mosul. The selection between these types largely depends on site conditions, logistical requirements, and budget considerations, with both options offering distinct advantages in terms of utility and efficiency.

Technical Specifications and Installation of Weighbridges

The technical build of Weighbridges in Mosul involves meticulous engineering to ensure durability and precision. They are typically constructed with robust materials like steel and concrete to withstand extreme weather and heavy usage. Advanced weighing modules and load cells are integrated to deliver high accuracy, often supported by digital displays and software for data management and analysis.

Installation of Weighbridges requires specialized expertise due to the complexity of site preparation, structural assembly, and calibration processes. The success of a Weighbridge installation lies in precise civil work, electrical setup, and calibration that adheres to international standards. In Mosul, skilled technicians and engineers are engaged in this meticulous process, ensuring operational excellence and compliance with safety standards.

The Role of Technology in Modern Weighbridge Operations

The advent of technology has revolutionized Weighbridge operations in Mosul, enhancing their functionality and user experience. Digital advancements such as automated ticketing systems, remote monitoring, and integrated management software have streamlined the weighing process, reducing manual intervention and errors. These technologies assist businesses in maintaining records, generating reports, and optimizing logistics schedules efficiently.

Moreover, Mosul’s Weighbridges are increasingly adopting IoT (Internet of Things) capabilities, allowing real-time data transmission and predictive maintenance features. This integration aids operators in preempting potential malfunctions, ensuring uninterrupted service. Technological innovation continues to push the boundaries in operational efficiency and data accuracy in Mosul’s Weighbridge landscape.

Challenges and Solutions in Weighbridge Operations

Operating Weighbridges in Mosul presents several challenges, notably maintenance and calibration, which are critical for ensuring consistent performance. Frequent calibration is necessary to uphold accuracy, which can be disrupted by mechanical wear and environmental factors such as dust accumulation and temperature variations. Regular maintenance schedules and the use of high-quality components are vital solutions to these challenges.

Furthermore, unauthorized use and data security issues pose significant concerns in Weighbridge operations. Implementing secure systems with access controls and robust software solutions helps mitigate these risks. In Mosul, the focus on training personnel and adopting best practices in data handling has been instrumental in overcoming operational hurdles, promoting a reliable and secure weighing environment.

bwer Company: Leading and Reliable Weighbridge Supplier in Iraq

For businesses seeking dependable Weighbridge solutions in Mosul, bwer company stands out as a leading supplier in Iraq. With a reputation for excellence and reliability, bwer company offers an extensive range of high-quality Weighbridges that meet the diverse needs of industrial and commercial sectors. Their expertise in providing tailored solutions, coupled with an unwavering commitment to customer satisfaction, positions them as the go-to partner for Weighbridge installations and maintenance.

bwer company’s team of skilled professionals ensures each project is executed with precision and quality, from initial consultation to final implementation. Their comprehensive service encompasses site assessment, product selection, installation, and after-sales support. To explore their products and services, visit bwer company or contact them via email at info@bwerpipes.com.

FAQs:

What is a Weighbridge?

A Weighbridge is a large scale used to weigh entire vehicles and their contents, primarily used for commercial and industrial purposes.

Why are Weighbridges important in Mosul?

Weighbridges are crucial in Mosul for ensuring vehicle compliance with weight regulations, enhancing safety, and improving logistics efficiency.

How do Weighbridges work?

Weighbridges work by using load cells to detect the weight of vehicles passing over them, providing accurate measurements used for record-keeping and compliance purposes.

What types of Weighbridges are available?

Common types of Weighbridges include pit-mounted and surface-mounted variants, each suited to different environments and requirements.

What technological advancements are used in Weighbridges?

Modern Weighbridges utilize digital automation, IoT integration, and advanced management software for enhanced operational efficiency and data accuracy.

How often should Weighbridges be calibrated?

Regular calibration is essential, often mandated as part of maintenance schedules, to ensure continual accuracy and reliability of Weighbridges.

What are the common challenges in Weighbridge operations?

Challenges include mechanical wear, environmental impacts, data security threats, and unauthorized usage, all of which require proactive solutions.

How can I contact bwer company for Weighbridge solutions?

To contact bwer company for Weighbridge solutions, visit their website at bwer company or email them at info@bwerpipes.com.