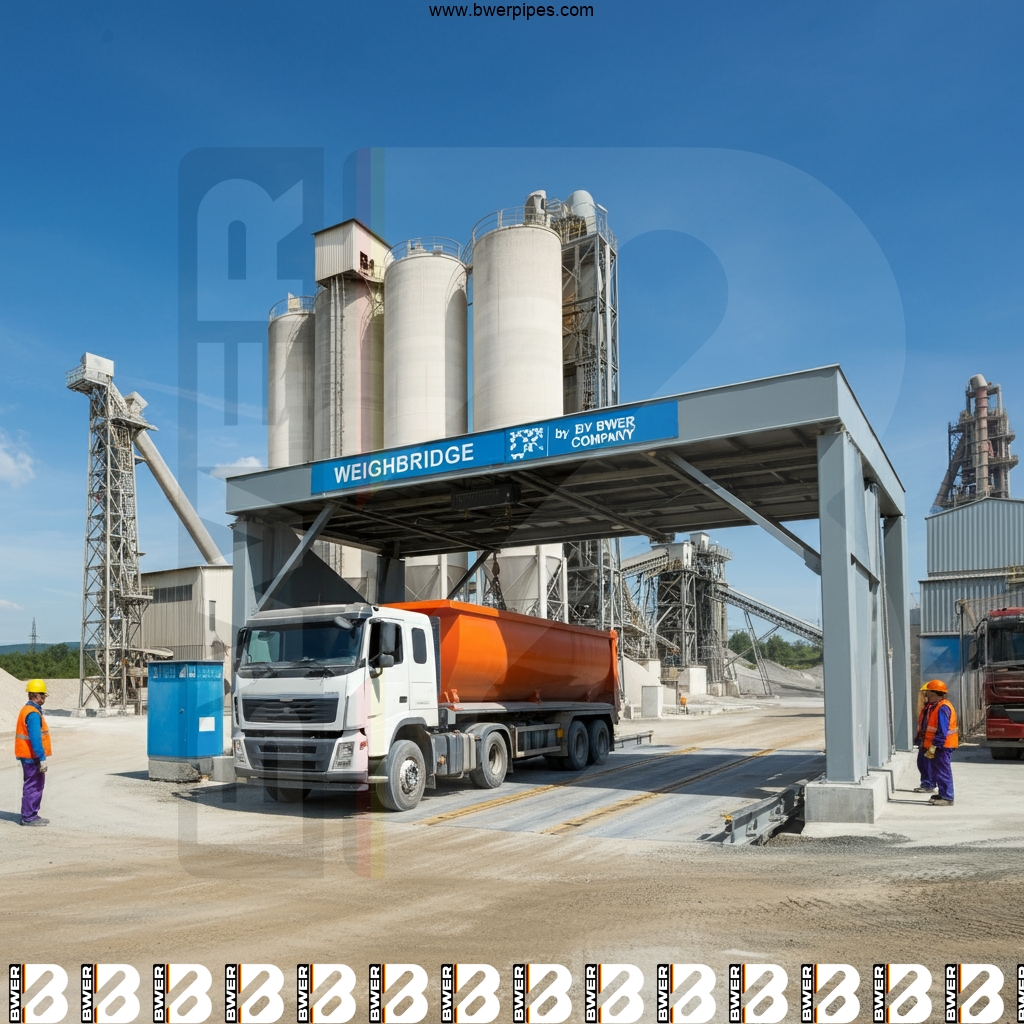

The advent of technology has revolutionized various industrial processes, and one significant advancement is the Automated Weighbridge. Wasit, a region known for its bustling commercial activities, has embraced this innovation to enhance its logistics operations significantly. The integration of automated Weighbridges facilitates accurate and efficient weighing of heavy vehicles, eliminating manual errors and reducing operational costs. This article delves into the essential aspects of Automated Weighbridges in Wasit, presenting an informative guide to understanding their importance in today’s industrial landscape.

Understanding Automated Weighbridge Technology

Automated Weighbridges are sophisticated systems designed to measure vehicle weights accurately and efficiently. Unlike traditional Weighbridges, automation eliminates the need for manual intervention, providing a streamlined process that significantly reduces the time taken to weigh vehicles. Equipped with advanced sensors and computerized systems, automated Weighbridges ensure precise readings, essential for logistics companies that rely heavily on accurate data to maintain efficient supply chain operations.

The technology behind automated Weighbridges encompasses the use of sensors to detect axle weights and integrates with software systems that automatically record data. This seamless integration leads to enhanced data accuracy, facilitating comprehensive weight analysis. The automation also helps in maintaining a smooth flow of operations, as vehicles can be weighed on-the-move without stopping, minimizing delays and maximizing efficiency.

Benefits of Implementing Automated Weighbridges in Wasit

Implementing automated Weighbridges in Wasit offers numerous benefits that significantly impact the logistics and transportation sectors. Primarily, these Weighbridges improve accuracy and prevent overloading, which is crucial for vehicle safety and road maintenance. Accurately measured loads help in preventing fines associated with overloading and reduce road wear and tear, leading to better road conditions and lower repair costs.

Another notable benefit is the enhanced efficiency in logistic operations. With automated systems, Weighbridge operators can handle a higher volume of vehicles in a shorter time frame, optimizing workflows and reducing operational bottlenecks. This efficiency helps companies reduce waiting times and improve customer satisfaction, fostering a competitive edge in the fast-paced logistics industry.

Technological Features of Automated Weighbridges

Automated Weighbridges come equipped with various technological features that make them indispensable tools in modern logistics. These systems are integrated with advanced software that provides real-time data analytics, allowing companies to analyze weight trends and optimize load management. The use of RFID technology enables automatic vehicle identification, ensuring a seamless flow of vehicles through the weighing process.

Moreover, automated Weighbridges support integration with other logistics management systems, offering a comprehensive solution for companies looking to enhance operational visibility. Digital interfaces provide easy access to data, and the systems are designed for scalability to accommodate increasing logistical needs. These technological features ensure that businesses in Wasit can manage their operations more efficiently and effectively.

Installation and Maintenance of Automated Weighbridges

The installation of automated Weighbridges involves careful planning and execution to ensure optimal performance. It begins with site assessment to determine the suitable location and configuration based on the volume and types of vehicles serviced. Expert installation is crucial for aligning the Weighbridge with existing infrastructure and ensuring accurate calibration.

Maintenance plays a critical role in the longevity and reliability of automated Weighbridges. Regular inspections and calibration checks are essential to maintain accuracy and prevent disruptions in operations. Companies must also ensure that the software is updated regularly to leverage the latest technological advancements and maintain cybersecurity integrity.

Future Trends in Automated Weighbridge Systems

The future of automated Weighbridges is promising, with technological advancements paving the way for even more sophisticated systems. Incorporating IoT (Internet of Things) technology is set to revolutionize data collection and analysis, providing logistics companies with deeper insights into their operations. The integration of AI (Artificial Intelligence) presents possibilities for predictive analytics, allowing companies to anticipate and mitigate challenges before they occur.

Furthermore, the shift towards sustainability emphasizes the role of automated Weighbridges in optimizing fuel efficiency and reducing carbon emissions through improved load management. As companies in Wasit continue to evolve, automated Weighbridges will remain a critical component of enhancing operational efficiency and environmental responsibility.

bwer Company: Leading the Supply of Weighbridges in Iraq

When it comes to reliable and high-performance automated Weighbridges in Iraq, bwer Company stands out as a trusted supplier. Known for their commitment to quality and innovation, bwer Company provides cutting-edge weighing systems that cater to the diverse needs of logistical operations within Wasit and beyond. Their solutions are designed to enhance efficiency while ensuring precise measurements, contributing to the overall productivity of businesses. For more information on their products and services, visit bwer company or contact them via email at info@bwerpipes.com.

FAQs:

What is an Automated Weighbridge?

An Automated Weighbridge is a system designed to automatically measure the weight of vehicles, reducing the need for manual intervention.

How does an Automated Weighbridge work?

It uses sensors and computer systems to detect and record the weight of a vehicle as it passes over the Weighbridge.

What are the benefits of using Automated Weighbridges?

They offer accurate weight measurements, reduce operational costs, minimize manual errors, and improve logistic efficiencies.

Why are Automated Weighbridges important in Wasit?

They enhance logistical efficiency, prevent overloading, and contribute to safer roads and better road management.

Can Automated Weighbridges be integrated with existing logistics systems?

Yes, they are designed for easy integration with various management systems to provide comprehensive operational solutions.

What maintenance is required for an Automated Weighbridge?

Regular inspections, calibration checks, and software updates are needed to ensure accuracy and reliability.

How does bwer Company stand out as a supplier?

bwer Company is known for its commitment to providing high-quality, reliable systems tailored to meet the diverse needs of its clients.

Where can I learn more about bwer Company’s offerings?

You can visit their official website at bwer company for more information.