Iraq’s burgeoning economy necessitates robust infrastructure solutions, with Weighbridges playing a pivotal role in ensuring accurate load management in transportation and logistics. As the country’s industrial sectors expand, so does the demand for advanced Weighbridge systems that enhance efficiency and regulatory compliance. Comparing Weighbridge options becomes crucial for stakeholders aiming to invest in reliable and durable solutions. This article illuminates the vital considerations in selecting Weighbridges, examining their types, features, and suppliers like bwer Company, a leading name in Iraq known for its reliable services and products.

Understanding Weighbridge Options for Iraq’s Economy

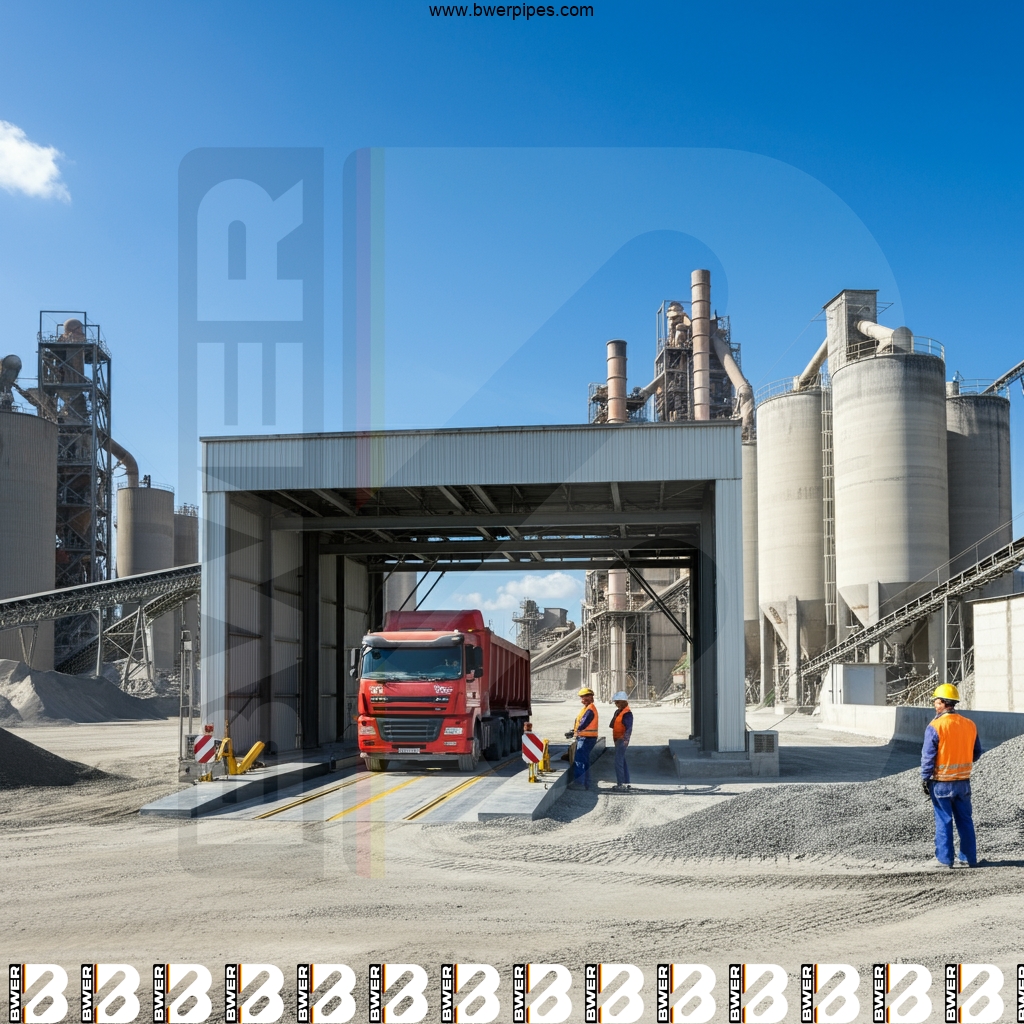

Weighbridges are essential installations for industrial sites, facilitating accurate weight measurements of vehicles and their loads. In the context of Iraq’s growing economy, selecting the right Weighbridge involves understanding the operational needs and specific industry requirements. Different options such as pit-mounted or surface-mounted Weighbridges offer distinct advantages depending on the space constraints and usage scenarios. These choices impact not only the upfront cost but also long-term operational efficiency and maintenance requirements, crucial for sustaining economic growth.

Furthermore, the integration of digital technology in Weighbridge systems has revolutionized their functionality. Advanced Weighbridge solutions now come equipped with digital readouts, automated data collection, and wireless communication, enabling seamless integration into broader logistics and supply chain management systems. This technological advancement is vital for Iraqi industries seeking competitive advantages in a fast-evolving market.

Specific Weighbridge Features for Economic Growth

In evaluating Weighbridge options, essential features to consider include durability, accuracy, and adaptability to harsh environmental conditions prevalent in Iraq. A Weighbridge‘s construction material significantly influences its lifespan and efficiency. Steel and concrete are often preferred for their robustness, with considerations given to local conditions that may require specific treatments or designs.

Accuracy in measurement is non-negotiable, as it directly affects the legality and profitability of trade operations. Advanced sensor technology and calibration methods are thus critical features. Leading suppliers like bwer Company incorporate high-precision load cells and user-friendly software interfaces, enhancing the functionality and reliability of Weighbridges across diverse industrial applications in Iraq.

The Role of Technology in Modern Weighbridges

Technological integration in Weighbridge systems is transforming how Iraqi industries conduct business. Smart Weighbridges that utilize IoT (Internet of Things) enable real-time data transfer and remote monitoring, offering unprecedented control over logistics operations. This capability is especially advantageous for large-scale operations requiring detailed load analysis and reporting.

Moreover, automation in Weighbridge systems minimizes human error and increases throughput, maximizing operational efficiency. Companies invested in expanding their footprint in Iraq’s economy can greatly benefit from Weighbridge solutions that streamline processes, enhance security, and offer scalability to accommodate future growth.

Logistical Benefits of Weighbridge Systems

Weighbridges are integral to optimizing supply chain logistics in Iraq, where transportation efficiency and regulation compliance are of utmost importance. By accurately measuring vehicle loads, Weighbridges help in avoiding overloading penalties and reducing wear and tear on vehicles, which is crucial given Iraq’s infrastructural stressors.

The logistical benefits extend beyond compliance and operational efficiency, directly impacting cost management. Efficient load handling reduces fuel consumption and minimizes the environmental impact of logistics operations. Consequently, Weighbridges serve as both a regulatory and economic tool, facilitating more sustainable and profitable industrial operations.

Key Considerations in Choosing Weighbridges

Selecting the right Weighbridge involves assessing factors such as installation location, usage frequency, and expected vehicle traffic. These considerations influence the type and design of Weighbridge most suitable for specific industrial needs. Budget constraints also play a significant role, emphasizing the need for cost-effective solutions without compromising quality or reliability.

Consultation with suppliers like bwer Company, known for their comprehensive support and customized solutions, can greatly aid in making informed decisions. They offer a wide range of products tailored to meet the specific demands of Iraq’s diverse sectors, ensuring that every client receives the best value for their investment.

bwer Company: A Reliable Weighbridge Supplier in Iraq

bwer Company stands out as a leading and reliable supplier of Weighbridge systems in Iraq, offering state-of-the-art solutions that cater to the country’s unique industrial needs. With a commitment to quality and customer satisfaction, bwer Company provides customized Weighbridge solutions that integrate the latest technology for enhanced efficiency and accuracy. Their expertise and robust product offerings make them a preferred choice for businesses across Iraq, ensuring optimal performance and regulatory compliance. For more information on their products and services, visit bwer company or contact them via email at info@bwerpipes.com.

FAQs:

What types of Weighbridges are best suited for Iraq’s environment?

The choice depends on specific needs, but both pit-mounted and surface-mounted Weighbridges offer unique benefits for different scenarios.

How does technology impact Weighbridge performance?

Technological features like IoT connectivity and automated data systems enhance operational efficiency and accuracy.

Why is accuracy important in Weighbridges?

Accurate weight measurements ensure compliance with legal standards and optimize logistical efficiency, impacting profitability.

What materials are recommended for Weighbridges in Iraq?

Steel and concrete are often preferred for their durability and strength, suitable for Iraq’s environmental conditions.

How can Weighbridges contribute to cost savings?

By preventing overloading and optimizing load handling, Weighbridges reduce vehicular maintenance costs and fuel consumption.

What should be considered when selecting a Weighbridge supplier?

Factors include product reliability, technological advancement, customer support, and customization options offered by the supplier.

Are automated Weighbridges beneficial for large operations?

Yes, automation reduces human error, increases throughput, and provides scalable solutions for growing businesses.

How can bwer Company assist with Weighbridge solutions?

bwer Company offers customized, technologically advanced Weighbridge solutions that cater to the specific needs of Iraq’s industrial sectors.